Siemens Fuel Gasification Technology at a Glance

Siemens Fuel Gasification Technology Disclaimer This document contains forwardlooking statements and information – that is, statements related to futu re, not past,

WhatsApp)

WhatsApp)

Siemens Fuel Gasification Technology Disclaimer This document contains forwardlooking statements and information – that is, statements related to futu re, not past,

Texaco Gasification Process includes equipment for slurry feeding, gasification, gas scrubbing, slag removal, clarifier solids removal, and process water handling. Figure 2 is primarily a schematic flow diagram of the process equipment and flows within the HPSGU II used in this demonstration. Secondarily, Figure 2 defines the interaction of ...

This plant uses petroleum coke or coal coke to produce synthetic gas, which can be raw material for the manufacturing of many chemicals such as ammonia, methanol, hydrogen cyanide, etc., and fuel for electrical power plants. This complete plant includes coke handling system, gasification reactors, syngas scrubber and purification system, as well as slag treatment system.

tiles, and construction building products. TEC has been marketing slag from its existing units for such uses for over 25 years. All of the water from the gasification process is cleaned and recycled, thereby creating no requirement for discharging process water from the gasification system.

Current Experience with Gasification Slag Utilization In addition to the successful assessment of Wabash slag to produce lightweight aggregate, the Polk plant has successfully processed slag for use in cement production. In order to meet the required slag specification, the size of the fines handling system was doubled, and additional slag ...

GASIFICATION TECHNOLOGIES – 2006 THE LONG LAKE INTEGRATED UPGRADING PROJECT Page 5 of 9 Through the upgrading and gasification processes that convert the heavy bitumen hydrocarbons to more useful forms, the metals in the crude become concentrated in the gasifier feed and subsequently in the gasifier soot.

Apr 18, 2002· The sump 12 usually has therein grinding means (not shown) to break up the slag it receives from the gasifier operation. The slag handling portion of the subject system has a lockhopper 14 with a first pressure lock 16 connecting the output of sump 12 to the input of lockhopper 14 and a second pressure lock 18 serving for its output

The Wabash River Coal Gasification Repowering Project is one of two demonstrations of advanced integrated gasification combined cycle (IGCC) technology in the United States. It was selected by the Department of Energy (DOE) in September of 1991 as a Round IV Demonstration Project for the Clean Coal Technology (CCT) Program.

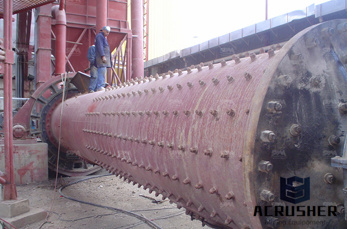

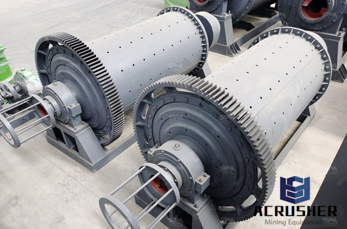

Slag conveyor for gasification furnace Boiler Manufacturers, Factory, Suppliers From China, We have now designed a reputable track record among many shoppers. Qualitycustomer initially are normally our constant pursuit. We spare no attempts to produce greater solutions. Stay up for longterm cooperation and mutual positive aspects!

Effect of Slag Tap Size on Gasification Performance and Heat Losses in a QuenchType Coal Gasifier ... The experimental system includes the following major sections: solids handling, solids feeding, gas feeding, gasification, syngas cooling, ... The gasifier consists of a gasification section and a slag quench section. The gasification section ...

Gasification Systems and Suppliers . Scott Valley Greenhouse Heating Gasifier. The links below bring up the web page of the gasifier listed. The menu at left, brings up stories on this web site. GASIFIERS FOR SMALL POWER GENERATION ... design and installation of Agricultural and Industrial Systems for Materials Handling, Air Quality and Biomass ...

Slag and Ash As discussed in the Background, solid waste from conventional pulverized coalfired power plants is a significant environmental issue due to the large quantities produced, chiefly of coal fly ash, and the potential for leaching of toxic substances ( heavy metals such as lead and arsenic) into the soil and groundwater at disposal sites, and accidental releases from coal ash ponds.

gasifier slag handling system vendors Gold Ore Crusher. gasifier slag handling system vendors. DOE ... The slag handling system removes solids from the gasification process equipment. ... Crushing Equipment; Grinding Mill; Free Chat. Name Of Industries In Which Denver Jaw Crusher Is .

The slag crusher . manufacturer of slag crusher, lag grinding mill and other slag mining equipment. US Patent # 5,166,109. Utilization of slag from coal gasification . Utilization of slag from coal gasification systems . from the system by equipment . screening the coal ash slag, recovering excess char from the screened coal ash ...

EPA/600/R12/540 June 2012 Version Technology Assessment Report Aqueous Sludge Gasification Technologies Prepared by: Greenhouse Gas Technology Center SEPA Operated by Southern Research Institute Under a Cooperative Agreement With Environmental Protection Agency

In order to meet the required slag specification, the size of the fines handling system was doubled, and additional slag Fusibility and flow properties of Shell gasifier slag–《Journal The fusibility and flow properties of Shell gasifier slag were study in this physical properties of slag were analyzed with Xray fluorescence,Xray ...

The ash content of a coal impacts the performance of the slag tap, the slag handling systems, but also to a certain extent the gasification performance, since molten ash in the form of slag on the wall of the gasifier forms part of the "insulation" which prevents excessive heat loss during the gasification .

Texaco Gasification Process Introduction In 1980, the Congress passed the Comprehensive ... The lockhopper system discharged the slag solids to a shaker screen which separated the slag into a coarse fraction (coarse slag), and a fine fraction (fine slag). The fine slag was recovered using a vacuum belt ... handling, and treatment prior to ...

article{osti_, title = {Coal pressurization and feeding use of a lock hopper system}, author = {, R. and Santore, R. R. and Dubis, D.}, abstractNote = {A necessary preliminary step in the Synthane highpressure coal gasification processes is to take ground coal at atmospheric pressure and feed it to the gasification system at operating pressure.

the grinding stage to ensure that the slag is fluid at the firststage temperature. Molten slag flows to the bottom of the gasifier, where it is quenched and then removed for sale or disposal. The gasifier is capable of handling a wide range of feedstocks. In the EGas™ Gasifier, the slurry feed is almost completely converted to a syngas ...

Fig. shows a schematic of the gasifier island including the full quench gasifier, the high dense flow dry coal feeding with lock hopper system and feeder vessel, the raw gas treatment, the black water treatment, and the vitrified slag handling system (Siemens, 2012).

Abstract. This report describes a first phase of a project to design, construct and commission an integrated coal/biomasstoliquids facility at a capacity of 1 bbl. /day at the University of Kentucky Center for Applied Energy Research (UKCAER) – specifically for construction of the building and upstream process units for feed handling, gasification, and gas cleaning, conditioning and ...

CAER Factsheet Demonstration of a Beneficiation Technology for Texaco Gasifier Slag. The dewatered slag product is loaded into trucks for offsite use or onsite storage. Water removed is pumped to the gasification process black water handling and processing system.

plasma gasification process. The syngas cleanup process removes unwanted chemicals from the syngas, preventing harm to human health, the environment and the facility''s equipment. Syngas cleanup options are based upon feedstock and syngas application (ie: electricity or liquids). Based on the plasma gasification facility''s inputs and

WhatsApp)

WhatsApp)