grinding equipment_Ball mill_Coal mill_Pipe mill_Veritcal ...

Lvssn provides various grinding equipment for cement production line, including: Grinding mill,Ball mill,Rod mill,Roller press,Veritcal mill,Pipe mill

WhatsApp)

WhatsApp)

Lvssn provides various grinding equipment for cement production line, including: Grinding mill,Ball mill,Rod mill,Roller press,Veritcal mill,Pipe mill

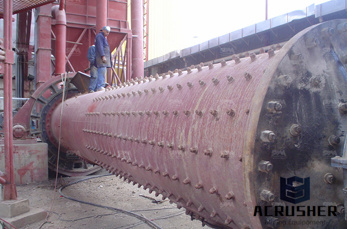

providing extensive modifications to a lime slaking mill. Working with the mine to develop an ideal solution for the existing 8by3feet Hardinge conical ball mill, the ETO grinding team proposed a redesigned mill including shell, trunnions and trunnion bearing assemblies all engineered to utilize the existing foundation and drive arrangement.

A wide range of modifications and upgrades are available for your BW Roll Wheel™ rollertype or E/EL ballandrace new components and technologies can be retrofitted onto existing pulverizers to provide you with the latest designs and operating benefits which can increase availability and reliability and reduce maintenance.

Pressure and temperature measuring system In order to understand the processes which occur during grinding with ball mills ( chemical reactions, phase changes), it is helpful to record the most important thermodynamic parameters: pressure and temperature. Planetary ball mills are frequently used for the development of new materials by mechanical alloying due to their high energy input.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silies, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill .

Ball charge modification. Ball top size. Marked ball test. Volume load. Mono ch. mill (H/D method) ... but Users need a certain experience to implement results of these calculators . Sizing equipments and mill''s optimization are the job of material suppliers and experienced engineering offices. ... Ball mill''s internals simulation ...

There are 3 ball mills in our plant so we should differentiate between ball mill power and total power of ball mills which is sum of each ball mills power. By increasing throughput the mill power will increase too but it will also let us to send one of ball mills as a standby so .

Sag Mill Suppliers In India Copper sag mill manufacturers in india samacsag mill for copper sag mill manufacturers in india. ore processing plant sag mill manufacturer YouTube Dec 15, 2013, Sag Mill Supplier For Copper Ore Grinding In India, Rock. The leading suppliers of SAG type.

Sep 12, 2019· Certain modifications have been made in the design to improve the performance installation of Ball bearings, newly designed pulleys, and a .

Optimization of Cement Grinding Operation in Ball Mills Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with...

produce of color cement grinding in cement grinding mill YouTube. Jun 13, 2014, the ultrafine particles required in the finished cement, Portland cement, Obtaining this color requires some modification to the method of manufacture;, grinding Cement Ball Mill Mining Processing Machine In cement.

dynamics inside the ball mill in dependence of the lling volumes of suspension and balls by rst considering only balls without suspension and then modeling the suspensions'' in uence. From this we get estimates for the energy of balls hitting their surface, which is an important value for the company.

The ball mill discharge is feed to the top of the SKSSeparator. Cement grinding capacity of Ball mill increases by adjustment of air gap in the V Separator with proper air distribution. Maintaining uniform air gap between plates and steps in the VSeparator increases production of cement mill.

As a leader in cutting tool innovation, Harvey Tool designs and manufactures special end mills and cutters to meet your toughest challenges.

The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times. The PM 200 is a convenient benchtop model with 2 grinding stations. You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input. The unique combination ...

For the Ball Mill, its performance, life and so on will be related to the market share, but also the customer''s concern, but these properties are related to the structure, how the structure determines the performance of the Ball Mill in production In addition, in order to obtain better development, the machine needs to continuously integrate ...

Billet Aluminum Ball Mill Designed Long Handle Window Cranks Multiple Finishes AvailableCruise in style and dress up your vehicle with the Billet Aluminum Ball Mill Designed Long Handle Window Cranks. Combining beauty and functionality, these cran

The peripheral discharge type of BallRod Mill is a modification of the grate type, and is recommended where a free gravity discharge is desired. It is particularly applicable when production of too many fine particles is detrimental and a quick pass through the mill is desired, and for dry grinding.

Ball Mill LV TECHNOLOGY PUBLIC COMPANY LIMITED. Ball Mill LV Classifier and its unique seperation concept The principle of classification is same for, the rotor has much less work to accomplish and consequently the separation efficiency is the, Traditional Modification of Ball Mill Classifier. Contact Supplier

C6 C7 Corvette LS Series Ball Mill Coil Cover w/ Oil Fill Cutout Multiple Finishes AvailableStylishly cover your coils with this C6 C7 Corvette + LS Series Ball Mill Coil Cover w/ Oil Fill Cutout. This fantastic alternative to

Ball milling is suggested as a novel method for enhancing filler dispersion in different matrices that is environmentally and economically sustainable [85]. It is a solidstate mixing of powders, usually performed with ball mills, which enables intimate mixing of .

Ball Mill Circuit Energy efficient ball mill circuit – equipment sizing. The ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment sizing, selection and design however, the potential to improve the capacity of ball mill .

Modifiions in the circuit and the ball mill intermediate diaphragm grate design enabled the optimization of the grinding capacity of the conventional twocompartment ball mill cement grinding and classifiion circuit. Ball mill grinding and classifiion circuit capacity was increased by 10% and specific energy consumption of the ball . Get Price

Modification of cement ball mill steel ball. ... In addition to the formation of its own unique ball mill series, the energy saving transformation of the old ball mill has also been carried out. in this paper, the relevant situation is introduced as follows. Improvement of feeder in the past, the ball mill mostly used spoon head combined feeder ...

WhatsApp)

WhatsApp)