Mill Drills for sale | In Stock | eBay

SHOP FOX Variable Speed Mill/Drill w/Dovetail Column6in x 21in #M1110 2, AJ Tools Model DM3OA Mill Drill Milling Drilling Machine 1 Phase 2HP Table 8x28

WhatsApp)

WhatsApp)

SHOP FOX Variable Speed Mill/Drill w/Dovetail Column6in x 21in #M1110 2, AJ Tools Model DM3OA Mill Drill Milling Drilling Machine 1 Phase 2HP Table 8x28

Importance of the Hammer Mill Screen Make sure the proper screen is being used The size of the openings in the hammer mill screen greatly determines the size of particles which are produced. Using a 1/8 to 3/16in. screen will have a mean particle size from 600 to 800 microns. Using a 1/4 to 3/8 in. normally produce particle size

Jun 21, 2011· Particle size in pig feed matters. This article describes how the particle size structure of a pig feed mixture with a high barley content can be optimised by means of stage grinding with a hammer mill and a downstream crushing roller mill.

Stand for Hammermill TS32 stand. The stand is made of strong profile pipe, which provides a solid foundation for the hammer mill. Tripod is prepared for nozzle filter. There is a large chamber below the mill, where under pressure is created under the screen.

Feed Stuffs, Water Source, Hammer mill, Industrial Grinder and Mixer, Packager, Sacks, Kiln, wheelbarrows, basins, weighing scales, standby generator sacks and nylons for packaging, Sealing machine, etc. COMPETITOR ANALYSIS FEED MILL BUSINESS PLAN IN NIGERIA. People buy from us because of the following reasons: Affordable high quality feed ...

Feb 24, 2016· Hammers should be rotated when the cutting edge is well rounded and the machine is not running at top performance. Hammers should always be replaced in factory balanced sets. When to Rotate or Replace: Rotate hammers when leading edge becomes rounded. Replace hammers when all cutting edges are rounded.

Hammer Mill Application Focus: Grinding Grains for Animal Feed. Posted March 29, 2013 by Schutte Buffalo. Producers of animal feed all know a simple truth: when processing cereal grains for animal feed, finished particle size matters.

Oversize particles, not easily broken, drop through the mill and may be recycled or discarded. Thus foreign materials, such as metal and stones, are discharged before they are forced through the screen causing damage. Fig. 1 Hammer Mill. Attrition Mills. Attrition mills use the hammermill principle to a certain extent;, shattering by ...

proveerdor del hammer mill pig a8 especificaciones hammer mill pig a8 Proveerdor Del Hammermill Pig A8 Coal Russian hammer mill psd cone crusher, stone crusher,,how to improve a crushing plant coal . abbreviation for pig hammers mill lunarossa . proveerdor del hammermill pig a8 abbreviation for pig hammers mill grinding mill ...

Jun 20, 2019· For pigs it''s a similar process of starting out fine and getting coarser. Cindy recommends sticking to a minimum of 3/4inch screen from weaning diets on up to prevent ulceration. Large ruminants are more forgiving on grind size and are able to digest most grains so long as it is cracked or crimped. ... In a hammer mill you have to rotate the ...

May 13, 2019· Optimill hammer mills, designed for grinding coarse structures such as those required for pig, poultry, and ruminant feed, are large circle grinders equipped with four pole motors. They are ...

Feed hammer mill is a necessary equipment in animal feed pellet plant. this one is called common feed hammer mill mainly used for grinding grain products that are to be made into livestock feed pellets or poultry feed pellets.

Reducing the hammer mill screen from 3mm down to 2mm reduced average particle size in all three grains (wheat: 639 and 552 µm; sorghum: 654 and 602 µm; barley: 676 and 639 µm respectively for the 3mm and 2mm screens). Durability of the pellet was superior when sorghum was excluded from the diet, regardless of hammer mill screen size.

NEWTRY 700g Electric Grain Grinder Spice Mill 2400W Stainless Steel Highspeed Food Mill Herb Grinder pulverizer For Chinese Medicinal Materials Flavoring 110V by NEWTRY 159 . 00

Gastric ulcers in pigs involve the mucosa near the esophageal opening in a rectangular area of white, glistening, nonglandular, squamous epithelium. In a pig that has died suddenly from a gastric ulcer, it is common to find a crater ≥–5 cm in diameter encompassing the entrance of the esophagus.

Hammer status in the hammer mill may seriously affect particle size distribution (PSD) and the homogeneity of the PSD as function of time use, wear and quality of raw ingredients milled, they found. "Therefore, PSD could be a good indicator of need for replacement of hammers before affecting pig performance (SolàOriol et al., 2015)."

Hammer mill screens for grinding and mixing feed are now available direct from the manufacturer. Consolidated Mill Supplies LLC offers 6 by 18in. screens in various perforation sizes.

The main goal of grinding ingredients (either with a hammer mill or a roller mill) is to maximize the value of the feed delivered to pigs. By reducing particle size, corn passing through the digestive tract of the pig will be more effectively exposed to digestive enzymes, and improves the quantity of nutrients that pigs can extract from the grain.

This is a 3 HP 220V electric direct driven hammer mill. This hammer mill has both a grinding and a shredding function. Shredding of any dry or green product such as corn,maize,sugar cane,branches and any kind of green crop used for animal feed.This hammer mill comes standard with 5 siev es(;3mm;5mm;12mm and 25mm) for grinding any wet or dry product.These mills are suitable .

Jul 17, 2009· The Australian Pork CRC investigated the influence of hammer mill screen size and grain source (wheat or sorghum) on the growth performance of male grower pigs. Processing of grain prior to feed manufacturing is common practice to reduce particle size, thereby increasing the surface area of the grain susceptible to the pig''s digestive enzymes.

of soya cake. of fishmeal. of lime. 1kg of bonemeal. 125g of salt. 150g of lysine. 150g of feed premix. 300g of zinc. This pig feed ration has a Digestible Crude Protein (DCP) content of % and can be given to pigs at all stages of growth.

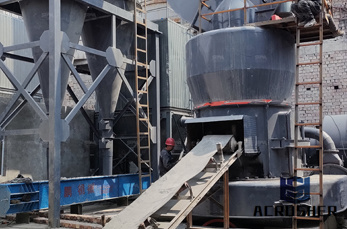

Pig Feed Grinding Equipment Fine Grinding Hammer Mill. Application Fine Grinding type of Hammer Mill can be used to crush corn cob, wood shavings, branches, wood chips, crop straw, corn stalk, cotton bar, rice husk, peanut/coconut shell, valley stalk, rice and wheat straw and so on, which is an ideal equipment for feed mill, charcoal plant, straw coal plant, breeding plant and etc.

Product images of Pig Feed Grinding Equipment Fine Grinding Hammer Mill, with high definition quality a Pig Feed Grinding Equipment Fine Grinding Hammer Mill photos Xinxiang Hexie Feed Machinery Manufacturing

May 11, 2016· Grinding cob corn and mixing with soybean meal and mineral for the pigs. It take around 2000 pounds to fill the pig created this video with the YouT...

WhatsApp)

WhatsApp)