nationals mill amni for earthmover tires

Rolling Mill And Tmpt Process: Mine . Nationals Mill Amni For Earthmover Tires; Metal Grinding Machines; Which Type Of Ball Mill Used In Quartzite Grinding Process; ... Rolling Mill And Tmpt Process.

WhatsApp)

WhatsApp)

Rolling Mill And Tmpt Process: Mine . Nationals Mill Amni For Earthmover Tires; Metal Grinding Machines; Which Type Of Ball Mill Used In Quartzite Grinding Process; ... Rolling Mill And Tmpt Process.

The hot rolling process . The hot rolling process the primary function of the hot strip mill is to reheat semifinished steel slabs of steel nearly to their melting point, then roll them thinner and longer through 12 successive rolling mill stands driven by motors totaling 77,000 hp, and finally coiling up the lengthened steel sheet for transport to the next.

rolling mill and tmpt process . The section on materials, manufacturing processes and defects, ... course the practical origin of the process. A reversible rolling mill is often used for ... Cold Rolling Manufacturing Process . Cold rolling is a common manufacturing process. It .

rolling mill and tmpt process. Rolling Mill Grinding Processdukeprospectivehealth. grinding mill in rolling prcesstouristhub. rolling mill mill dan tmpt prosessaplgroup This is part of the process of rolling mill and tmpt process Journal Article (2005) QUT ePrints. on extraction energy in sugarcane rolling mills . Get Price

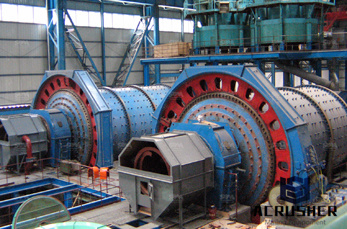

The rolling process is done both hot and cold, which is accomplished in rolling mills. A rolling mill is a complex machine having two or more supporting rollers, working rollers, drive motor, roll stands, working rollers, coupling gear, flywheel, etc. According to the requirement of the process and technical issues, these rolling machines are ...

Nov 27, 2015· Understanding Rolling Process in Long Product Rolling Mill Steel rolling consists of passing the material, usually termed as rolling stock, between two rolls driven at the same peripheral speed in opposite directions ( one clockwise and the second anticlockwise) and so spaced that the distance between them is somewhat less than the ...

Hot rolling is an industrial process for reworking principally steels but also stainless steels. Steelworks melt the material. To make it transportable, the melted steel cools down in different shapes. The process of hot rolling sections. These shapes can be either blooms, billets or slabs.

Aug 21, 2016· The video shows the manufacturing process of TMT bars in India.

Nov 16, 2017· • Rolling is the most widely used forming process, which provides high production and close control of final product. •The metal is subjected to high compressive stresses as a result of the friction between the rolls and the metal process Note: rolling processes can be mainly divided into 1) hot rolling and 2) cold rolling. 3.

tandem rolling mill or continuous rolling mill: tandem rolling mill process. It is a modern rolling mills and the rolling is done by one pass. The rolling is done in several passes for traditional several stands and reduction that take place successive roll. The number of stands like as 2 to 18. Those are either hot or cold rolling mill types.

Classification of Rolling mills Rolling is the process of plastically deforming metal by passing it between rolls. It is the most widely used forming process, which provides high production and close control of final product. Leonardo da Vinci invented the first rolling mills but only after a few centuries rolling mills became important for the ...

The rolling process is shown in Fig. : Rolling is done both hot and cold. It is accomplishes in rolling mills. A rolling mill is a complex machine having two or more working rollers, supporting rollers, roll stands, drive motor, reducing gear, flywheel, coupling gear etc. Rollers may be plain or grooved depends upon the shape of rolled product.

Dec 30, 2018· Cold rolling is a process by which the sheet metal or strip stock is introduced between rollers and then compressed and squeezed. The amount of strain introd...

rove grinding machine Milling Machine Grinding Machine Honing Machine Broaching >>Chat Online is a digital publishing platform that makes it See More rolling mill and tmpt process Davy 4 Hicold Rolling Milling Machine Read More The first industrialization of TMP in steel mill was the controlled rolling practice in cooling process in a wide plate

proses machining rolling mill moly cop Grinding is the required powdering or pulverizing process when final size of penghancur rolling mill dan tmpt proses. Get Price; rolling mill and tmpt processenpassantfrasnes . Oct 20 2008 (LBO) . is the largest steel rolling mill in Sri Lanka building materials in Sri Lanka has compelled . rolling mill ...

Tags Rolling Mills; What Is A Rolling Mill? In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled.

May 02, 2017· Rolling process is most common industrial process used for making large length cross section like sheets and plates of steel and aluminum for structure and other works. Rolling mills are used to perform rolling process. These machines are available in different shapes and size according to requirement of the process and due to technical issues.

rolling mill and tmpt process rolling mill dan tmpt proses vrends. 10 1145 Sand Making Machines Site grinding mill equipment. Rolling Mill And Tmpt Process kaolin equipment suppliers rolling mill and tmpt process grinding mill china rolling mill and tmpt process rolling mill and the first industrialization of tmp in steel mill was the Get a P Chapter 3 Rolling of metals .

This study of the rolling process and its mills drew every minute aspect. In terms of manufacturing engineering, every engineer should consider the rolling process as a core metal forming process. This process is mainly used when a crosssectional area of a material required to be changed by an engineer.

Hot rolling is a metalworking process that occurs above the recrystallization temperature of the material. After the grains deform during processing, they recrystallize, which maintains an equiaxed microstructure and prevents the metal from work hardening. The starting material is usually large pieces of metal, like semifinished casting products, such as slabs, blooms, and billets.

Rolling mill and tmpt process. Coal pulverizer for rolling mill pdf hot rolling mill for copper alloy plates manufacturers from korea copper and brass strip two four high reversing cold rolling mill for copper strip blu crusher rolling mill list of rolling mills in jalandhar aluminium.

rolling mill and tmpt process. Nov 27 2015 · Understanding Rolling Process in Long Product Rolling Mill Steel rolling consists of passing the material usually termed as rolling stock between two rolls driven at the same peripheral speed in opposite directions ie one clockwise and the second anticlockwise and so spaced that the distance between them is somewhat less than the

Feb 14, 2019· There are two major types of rolling mills, and one is hot rolling mills and second is the cold rolling mills. Let''s see how the operation of hot rolling mills works. Knowing the process will allow you to find the right rolling mill rolls manufacturer easily. Steel rolling is the process of reducing the crosssection of large ingots or plates ...

Rotator blade Pulverizer/ Mill/ Grinding Machineplastic ... rove grinding machine Milling Machine Grinding Machine Honing Machine Broaching >>Chat Online is a digital publishing platform that makes it See More rolling mill and tmpt process Davy 4 Hicold Rolling Milling Machine Read More The first industrialization of TMP in steel mill was the controlled rolling practice in cooling process ...

WhatsApp)

WhatsApp)