Processing plant definition and meaning | Collins English ...

Jul 24, 2020· Processing plant definition: a factory where raw materials are treated or prepared by a special method, esp one where... | Meaning, pronunciation, translations and examples

WhatsApp)

WhatsApp)

Jul 24, 2020· Processing plant definition: a factory where raw materials are treated or prepared by a special method, esp one where... | Meaning, pronunciation, translations and examples

Jun 13, 2014· 5t/d Mobile Gold CIL Plant for Gold Ore Processing, Xinhai Duration: 0:46. Xinhai Mining 15,481 views. 0:46. James Baldwin Debates William F. Buckley (1965) Duration: 58:58.

Many gold plants use conventional thickening with flocculant addition. High rate thickeners, as well as dewatering systems that use cyclones only or cyclones and highrate thickeners can also be used in principle. Leaching reagents in the form of cyanide and an .

ghana gold and diamond processing plant south africa T19:12:50+00:00

Fimiston and Gidji Processing Plants. The Fimiston and Gidji Processing Plants were commissioned in 1989, with Fimiston undergoing two expansion stages to become one of the largest milling complexes in Australia. The sites treat more than 12 million tonnes of ore per year to produce up to 800,000 ounces of gold. The process of extracting gold ...

The SART process has been used successfully at several fullscale mining operations and more plants currently under construction. SGS is a leader in the SART process. We provide flowsheet development, testing, pilot plant development and ongoing support at fullsized operations using SART and other cyanide recovery processes.

Oct 26, 2011· Vetran miner Mike Reynolds takes us through a tour of a gold processing mill that he has been working on for several years. He explains the process of taking the raw material and extracting the ...

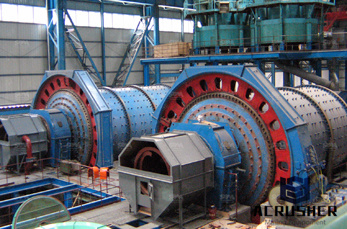

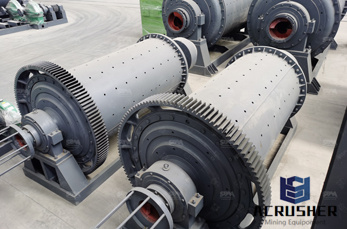

Gold Processing Plant, Carbon In Leach (CIL) Plant. A Carbon In Leach Gold Recovery Plant. This plant processes 4 million tons of ore per year with an average gold content of ounces of gold per ton of ore. Approximately 85% of the gold is recovered in the plant. From the ball and/or autogenous mill, slurry is pumped to the CIL leach tanks ...

Jul 23, 2020· We at APT are proud to bring you our RD50 and RD100 Hard Rock Processing Plants, offering highly economical solutions for rapid gold production on a small to medium scale. Leading on from our small scale RDGK, these two robust and compact solutions are .

The Boddington Process Plant is fully compliant with the International Cyanide Management Code and has recently undergone a recertification audit. Figure 5. Residue disposal area. References. Dunne, R., Hart, S., Parker, B. Veillette, G (2007). Boddington Gold Mine – An example of sustaining gold production for 30 years.

Operating Costs of Gold Processing Plant. The EXAMPLE Gold Mine Operating Manual has been prepared to provide a practical reference for operators in the EXAMPLE Gold Mines Processing Plant. This manual contains basic information about the process and equipment used in the process. Each unit is identified by name and equipment number.

Gold Processing Plants For Sale In Sweden. We are a professional mechanical equipment manufacturer, we provide original parts, service solutions, extensive training and extensive wear, crushing chambers and screening media solutions to reduce operating costs, improve product quality and maximum productivity.

Oct 20, 2014· Nature of Gold: The surface of a gold particle will typically be dissolved at a rate of around µm of surface depth per hour in a cyanide leach. For large gold particles and nuggets, this is too slow to be fully dissolved in a typical processing plant. Much simpler and less expensive gravity methods are available to recover this gold.

Gold processing, preparation of the ore for use in various products. Native gold is the most common mineral of gold, accounting for about 80 percent of the metal in the Earth''s crust. It occasionally is found as nuggets as large as 12 millimetres ( inch) in .

Jul 20, 2020· The two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process. The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold.

Alluvial gold processing plant / 90%+ Gold Recovery Ratio Hengcheng offers complete project solutions for Alluvial Gold Processing Plant. We are one of the leading project suppliers for Alluvial Gold Wash Plant Equipment and we work closely with our .

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration.

Ore processing At the processing plant, gold and silver are extracted from the ore. The processing plant alternates between treating ore from the Martha Mine open pit and from the Favona underground mine. Ore processing consists of the following stages:

gold processing plant cover copper ore liner_Gold mine copper processing plantYouTubeDec 09, 2016· Gold, Iron, Copper Processing Plant. industrial separation process of iron from iron ore [] grinding machine gold mine go. Tel WhatsApp:+86 158 0667 8589. E .

Gold and Silver Ore Processing and Recovery Plants for . Gold and Silver Ore Processing and Recovery Plants for Sale . Savona Equipment is your source for new, used, and reconditioned Ore Mineral Processing Plants of many types and capacity for large primary ore processing, secondary, and tertiary fine material concentrating as well as complete aggregate, recycling, mining, and .

Gold is set into anodes and suspended in porcelain cells. Cathodes are made up of pure gold strips. An electric current is passed through the anodes to the cathodes, which dissolves the anodes and separates the gold from other metals. This process takes about two days. Afterwards, the cathodes are melted and moulded into bars.

Apr 24, 2017· Gold Smelting Gold is purified by means of a smelting process, which utilizes pressure, high heat and chemicals to accomplish the task. Like any metal that appears naturally in the earth, there are impurities that must be removed.

Ore processing is a 24 hour operation. Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added (2) to raise the pH of the ore.

The process of panning and sifting for gold uses both of these methods. ... are generally employed for grinding purposes in a mineral processing plant. ... Gravity separation is one of the oldest technique in mineral processing but has...

WhatsApp)

WhatsApp)