Roller Mills | Milling | Group

The grinding gap on our roller mills can be adjusted manually or, on some models, automatically. If you adjust the grinding gap automatically, the adjustment can be based on your recipe or on particle size. .

WhatsApp)

WhatsApp)

The grinding gap on our roller mills can be adjusted manually or, on some models, automatically. If you adjust the grinding gap automatically, the adjustment can be based on your recipe or on particle size. .

Coal Crusher: Generally, require when ball mill is used for grinding and raw coal size is on higher side(>25mm). Conveying to Hoppers: Covered belt conveyors, horizontal or inclined are most suitable and commonly used for conveying.

coal grinding rollers Hungary laquo crusher plant; Radial Contact Ball Bearing In Nigria – xinhai. ... Coal Crushing Plant coal crusher plant coal crushing . has many years manufacturing experience in coal crushing plant (coal crushing process washing plant and belt conveyor) is a major coal .

The feeder (A) introduces raw material into the grinding chamber in the base of the Roller Mill (B) at a rate determined by pressure variations with the grinding mill. Plows located ead of each roller direct the material upward and between the grinding .

The vertical roller mill coal grinding system is generally composed of a vertical roller mill main body, a fine powder collecting device, a fan, and a pipeline. The working process is that the raw coal enters the vertical roller mill and is ground by the air (or hot air) into the classifier, and the fine coal .

A compact coal mill solution for grinding virtually any type of raw coal Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal. The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal, removing the need for a separate ...

Coal The coordinates of the grinding table diameter and number of rollers can be read off from the table. The xcoordinate indicates which product throughputs can be generated using the respective mills.

Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag. It has the features of simple structure and low cost of manufacture and use. Vertical roller mill .

Jul 19, 2018· In contrast, the Roller Mill Grinder Mixer operates at a much slower speed than the Hammer Mill Grinder Mixer. This type of grinder produces a more consistent particle size with increased bulk. The variable parameters of the Roller Mill are feed rate, quality of feed, and power to the Roller Mill .

Vertical Roller Mill NHI Group Vertical roller mill is a kind of energyefficient grinding machines, which is widely used in many fields such as producing raw and clinker material, grinding slag, ore, industrial silicon, calcium carbide residue, coal gangue in the cement industry and desulphurization process in the industries of coal,,

Raw Coal Hanging At Coal Grinding Mill. Coal Grinding Mill Roller Type VietnamFruit. Longlasting coal mill for efficient grinding fl. a compact coal mill solution for grinding virtually any type of raw coal our atox® coal mill is a compact vertical roller mill that can grind almost any type of raw coal the coal mill utilises compression and shear force generated between the large rollers

The feeder (A) introduces raw material into the grinding chamber in the base of the Roller Mill (B) at a rate determined by pressure variations with the grinding mill. Plows located ead of each roller direct the material upward and between the grinding rolls and the heavy alloy steel bull ring where it .

Jun 14, 2019· Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mill''s main components, how it works and some .

WD100 coal mill grinding roller repair welding wire, US 4 6 / Kilogram, Tianjin, China, WODON, WD100, WD100A, WD350, WD350A, WD650, WD650A, from Tianjin ...

MVR vertical roller mill for cement grinding and MPS vertical roller mill for pet coke grinding Another two Pfeiffer mills for Wonder Cement Wonder Cement belongs to a familyowned company .

Guizhou 80,000TPY Limestone Grinding Plant. Customer Address: Guizhou, China. Input Material: Limestone. Finished Particle Size: 180mesh, 250mesh

Coal dust is a type of fine coal powder ground by coal grinding mill, size range ~, and most of powder''s size range 20~50μm. Pulverized coal processed by grinding machine could be .

Pulverizers Coal Grinding Roller Mills William''s Vertical Roller Mill Pulverizers utilize centrifugal force to grind coal material while maintaining low operating costs. Featuring easily replaceable wear parts, automated process controls and infinite turndown thanks to VFAC drives, these machines are perfect to use as a coal mill.

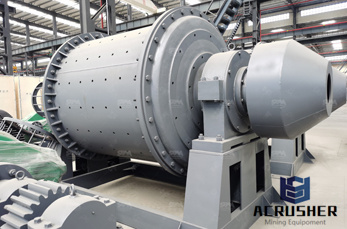

Hammer Mill adopts. More; Ball Mill Ball mill has been used in many industries for a long time, the technology is quite mature already. But there. More; MTM Series Trapezium Mill Raymond mill is ever one classic powder grinding machine in the past. And most of modern mill are from it and. More; LM Vertical Roller Mill Vertical Roller Mill ...

AGICO vertical coal mill has explosionproof system, can ensure production safety. Buy vertical coal grinding mill for cement plant and thermal power plant.

SVENMILL It is used for a variety of functions including grain grinding (Corn, Wheat, Barley, Pulses, Oil seeds, etc.) as well as many other materials (Fertilizer, Coal, etc.)? The design of our roller mill .

Raymond Coal Grinding Machine. Raymond grinding mill Raymond mill. Raymond Mill is also called Raymond roller millraymond grinding mill . talc ceramic iron ore carborundum bauxite rock phosphate coal and other . feeder will uniformly transfer the material into the grinding .

offers 1,373 roller mill for coal products. About 35% of these are mine mill, 1% are grinding equipment. A wide variety of roller mill for coal options are available to you, such as ball mill, raymond mill.

Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, and many other materials. ... MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, Croatia. MPS 100 GC vertical roller mill for the grinding, drying and calcining of gypsum, Trevo, Brasil.

WhatsApp)

WhatsApp)