Dry Process for Manufacturing of Cement GharPedia

Dry Process for Manufacturing of Cement. Materials. Jun 22, 2016 Ritesh Patel . Ritesh Patel. Mr. Ritesh Patel is a Civil Engineer who has earned Bachelor''s degree in 2005. .

WhatsApp)

WhatsApp)

Dry Process for Manufacturing of Cement. Materials. Jun 22, 2016 Ritesh Patel . Ritesh Patel. Mr. Ritesh Patel is a Civil Engineer who has earned Bachelor''s degree in 2005. .

The resulting cement slurry flows into storage tanks. Must Read: Dry Process For Manufacturing of Cement When lime stone is used, first blast it, then crushed in two .

The cement manufacturing is done by majorly by two methods known as wet process and dry process depending on their mixing is done with water or without water. The wet process of cement manufacturing too popular for several decades because of the possibility of more accurate control while raw material mixing.

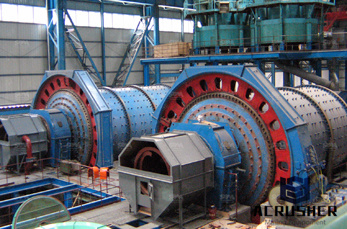

As cement clinker sinters, the temperature decreases, and then under the function of the cooling machine high temperature clinker will be cooled and discharge to storage. VI. Cement grinding. Final process is the cement grinding. But power consumption is the largest in the last process of cement manufacturing.

Course Program. Module 1: An introduction to the Cement Manufacturing. This module addresses the fundamental principles of cement production. Module 2: Raw materials for cement manufacture. In the cement industry, the quarry is the extraction method for the production of raw materials in the cement manufacturing process.

The dry process of cement manufacturing means that after raw materials with different particle sizes are dried, broken and ground into powders of certain fineness, they will be sent into the dry process .

From the limestone quarry to the delivery of the end product, follow every step in the cement manufacturing process. Step 1: extraction of raw materials The raw materials needed to produce cement (calcium carbonate, silica, alumina and iron ore) are generally extracted from limestone rock, chalk, clayey schist or clay.

A clean and revolutionary cold manufacturing process. Hoffmann Green has initiated a technological breakthrough based on changing the composition of cement so that it does not contain clinker, the main source of CO2 emissions in traditional cement production, as well as creating a cold and clean cement manufacturing process (no firing of raw materials).

Aug 28, 2018· Cement Manufacturing Process. Cement is the basic ingredient of construction and the most widely used construction material. It is a very critical ingredient, because only cement has the ability of enhancing viscosity of concrete which in returns provides the better locking of sand and gravels together in a concrete mix.

Dry Process for Manufacturing of Cement. Materials. Jun 22, 2016 Ritesh Patel . Ritesh Patel. Mr. Ritesh Patel is a Civil Engineer who has earned Bachelor''s degree in 2005. He is a senior editor at GharPedia and, core member of Editorial Team, senior manager at SDCPL (Civil Eng.). He looks after constructing a House, Concrete, Material ...

Jul 31, 2013· Cement manufacturing Process | How to make OPC PPC Cement by Kiln Dry Pyroprocessing system Duration: 12:39. Cementpdm 10,058 views. 12:39. Cement Manufacturing Process Duration: 2:22.

Coprocessing in cement production operations refers to the use of alternative fuels in both combustion and production processes. In terms of combustion, it involves .

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

The cement industry has boosted efficiency by concentrating new capital investment in plants that use the dry process of cement manufacture, and by phasing out operations that rely on the more energyintensive wet process. Since 1974, the number of wet process kilns has dropped from 234 to 25 a decline of 89 percent while the number of ...

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

Methods of Manufacturing Process of Cement. At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process. The main difference between these two methods of manufacturing of cement is that in the dry process, calcareous and argillaceous raw materials are fed into the burning kilns in a perfectly dry state.

Cement production processes can be categorized as dry, semidry, semiwet, and wet processes depending on the handling of raw material before being fed to the rotary kiln. Nowadays, almost all new plants are based on the dry process .

Jan 15, 2019· Green cement is a form of cement produced with the help of a "carbonnegative manufacturing process." In other words, cement produced as the final product of a technologically advanced process, such that emissions during unit operations (like clinker production) are minimized, is referred to as green cement .

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km.

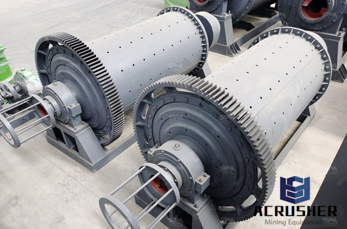

Jan 28, 2017· THE CEMENT MANUFACTURING PROCESS 1. RAW GRINDING : The raw materials are very finely ground in order to produce the raw mix. 1. RAW .

Process of Manufacturing of Cement The cement is manufactured by integrating the calcareous component and argillaceous component in a ratio of 3:1. The calcareous .

May 12, 2020· The cement manufacturing process is completed when the cooled clinker is ground once again in a rotating finishing mill. A combination of gypsum and limestone will usually be added in small amounts to the heated cement during this last grinding step, and coloring agents can also be added here. The fineness of the finished particles will vary according to individual preferences, and the cement ...

Aug 30, 2012· Cement Manufacturing Process Phase II: Proportioning, Blending Grinding. The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding. Generally, limestone is 80% and remaining 20% is the clay.

There are two different processes for manufacturing cement. wet process minerals are wet ground (by adding water) to form a slurry and then dried, dry process minerals are dry ground to form a powderlike substance. Both the processes are in use and have their own advantages and disadvantages.

WhatsApp)

WhatsApp)