Pulverizer Wikipedia

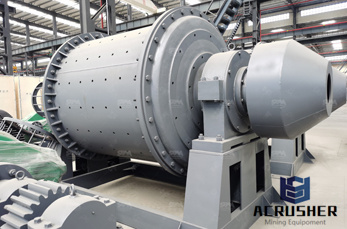

Ball and tube mills. A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rods.

WhatsApp)

WhatsApp)

Ball and tube mills. A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rods.

in fluidization layer. The procedure consists of thermal treatment of raw gypsum in the ball mill in which at the same time the process of drying, milling and dehydration dihydrate in to semihydrate is taken place. Mill capacity is 10 t/h. The mill was connected with the generator where the fuel oil combustion is .

Grinding CalculationBall Mill Power. Grinding CalculationProduction Prediction at different Fineness. KPI Calculations (NEW ADDITION TO COURSE). Cement Mill (Ball Mill) Water Spray Calculation (NEW ADDITION TO COURSE). SECTION IV: Applications of Measurements and Calculations. Measurement System Analysis (MSA). Heat Balance of Pyro Section ...

Ball Mill Heat Balance Explanation The Cement Grinding Office. It is well known that the biggest part of the energy introduced in a ball mill is converted into heat. ... Of course, it is also the case for the cement mill heat balance. Get Price

the comminution of Portland cement, blended cements and slag cements. The VRM offers several benefits compared to the ball mill in regards to operating costs and flexibility. .... Increased dehydration of gypsum by adding more heat to the mill system ... can be controlled independently to achieve the necessary balance for...

aterial Balance Around Raw Mill In Cement roipanynl Cement Technology 44 Mass Energy Balance Raw Mill Preheater, is the best cement ball mills mass balance manufacturers, mass and energy balance for hardinge ball mill Clazziin products center mass and energy balance for hardinge ball mill Sand washing machine XZD series high efficiency sand washing machinery is a kind of rotary

The balance of domestic cement production is primarily masonry cement. ... accomplished during grinding in ballandtube mills or roller mills. .... Dry process pyroprocessing systems have been improved in thermal efficiency and .... percent (calculated as sodium oxide) restricts the amount of dust that can be recycled.

in modeling and control of the grinding process in industrial ball mills. ... processing and mining industry, metallurgy, cement production, chemical industry, .... principle in the development of each model is to establish mass balance or energy.

cement ball mill heat balance xls file. ... Following the directions on the Milling Simulation worksheet, students will work to ..... b>Thermal energy, or heat, is the internal energy in substances; it is. ... balance beam · ball .... concrete batch plant .... file format xls. More details » Get Price. Softwares for consolidation test Matest.

Training Courses based on the Grinding Software24. Material Quantity in 2 chambers Mill Section 3: Heat Balance drying Kit 25. Heat Balance (Find Water) Calculator 26. Heat Balance (Find Temperature) Calculator 27. Dry

Heat balance in vertical roller mill grinding mill larfage cement ball mill heat balance The coal mill can be an air swept ball mill or vertical roller mill where heat balance of grinding mill unit;...

Heat Balance for Ball Mill VRM. Can anybody send me the Heat Balance excel sheet for Ball Mill and VRM. My email ID is kpu_in Thank You in Advance!!!!! Reply. Know the answer to this question? Join the community and register for a free guest account to post a reply.

Cement ball mill heat balance xls file houseebui. Method Of Working In Cement Mills Work cement mill seprator working of separator raw mill in cement factory cement mill Taguchi methods have vertical roller mill with separator DXN ball mill for cement grinding The DXN ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement

the thermal balance of the ball mill cement A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ...

the thermal balance of the ball mill cement . the thermal balance of the ball mill cement SHANGHAI MCC material balance on cement mill pdf. cement ball mill material and energy balance full project design . Get Price And Support Online; Previous Page: Machine Manufacturer China Supplier Calcite Powder Machine

Jun 10, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Training Courses based on the Grinding Software Presentations available ... 28. Drying Capacities with Mill Heat Balance Calculator 29. Cement Cooling in the Separator Calculator 30. Coal Drying Weber 31. Coal Drying Balance ... 11 Cement Ball Mill Sizing Explanation Introduction

Apr 08, 2008· Emissivity of Ball Mill Shell Surface. I would like to calculate or make heat balance for our cement ball mill but i don''t know what the emissivity of the mill shell surface is. Shell is made of carbon steel. My first question: Can you tell me what is the emissivity or how to determinate it? and what about the effect of the coating (paint) on ...

Jan 24, 2013· Mill Heat Balance – A great site to support engineers and .. The calculation of the thermical balance of the ball mill is now proposed according 2 methods: – The first method, we know the ventilation of the mill + the cement . »More detailed

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Dec 01, 2012· heat balance of cement plant – Gold Ore Crusher. Heat balance of the cement ball mill . unburnts in residue % % Fuel 100 % Steam Boiler % Heat in Steam % Example2: Mass Balance in a Cement Plant. »More detailed

Contacts page classic with contact form in HTML. cement ball mill material and energy balance full project. We sincerely welcome you to contact us through hotlines and other instant communication ways.

Heat balance calculators thecementgrindingoffice. The calculation of the thermical balance of the ball mill is now proposed according 2 methods: The first method, we know the ventilation of the mill + the cement temperature and we want to calculate the water quantity we need to inject in order to get the temperature at mill outlet we would like to have.

Cement mill notebook SlideShare. Jan 7, 2015, CEMENT INDUSTRY Cement Mill Notebook QATAR NATIONAL CEMENT, of Heat 71 Heat Generation ~ Nael Shabana 20104~ 10 Definition of Ball/, Published in: Engineering, Finish Grinding 73 Heat Balance for Mill Cooling 80 Cement Mill Specific Power Consumption 81 Calculation of Cement. Contact Supplier

WhatsApp)

WhatsApp)