aggregate aggregate crusher crushing iron ore

Iron Ore, Mineral Slag Crusher Stedman Machine CompanyMineral Rocks Ore Crushing Machines. Stedman impact crushers, mills, and grinders are used in nearly ev

WhatsApp)

WhatsApp)

Iron Ore, Mineral Slag Crusher Stedman Machine CompanyMineral Rocks Ore Crushing Machines. Stedman impact crushers, mills, and grinders are used in nearly ev

the iron sinks to the bottom. Impurities left in the ore combine with limestone to make SLAG

The ore is loaded into a blast furnace along with measured quantities of coke and limestone. Hot combustion air is supplied to the furnace and some form of fuel used to raise the temperature. The iron is reduced from the ore by carbon in the coke, the limestone aiding slag separation from the molten iron. The slag and molten iron are tapped off from the bottom of the furnace, the slag being ...

Iron Blast Furnace Slag (BFS) This is the coproduct from the reduction of iron ores to produce molten iron and molten slag. 1. When allowed to cool slowly to a crystalline rod< form It becomes a light gray vesicular rock known as AirCooled Blast Furnace Slag. Principle uses include:

SLAG is an industrial waste product – there is no standards about the quality of it. What is in it depends on what was the raw material used for the production of iron – scrape metal, iron ore,..

This process is used to make iron. The limestone forms a substance called slag with the rock of the iron ore. The bottom part of the furnace is called the hearth. When it has filled with liquid pig iron and slag, the slag is removed. This is called skimming. Slag is lighter than iron and does not mix with iron. It floats on top of the iron.

Lumps or fragments of manmade materials, ore rocks, slag (the byproduct of industrial processes) and the iron oxides magnetite and hematite, are also common all throughout the world and are frequently dense and metallic. So this test is helpful but not definitive. To measure the density of your rock, you need to measure its weight and its ...

Slag from steel mills in ferrous smelting, on the other hand, is designed to minimize iron loss and so mainly contains oxides of calcium, silicon, magnesium, and aluminium. Any sandy component or quartz component of the original ore automatically carries through the smelting process as silicon dioxide.

Different Types of Iron Ore. Previous Next View Larger Image ... because it is said to make a pasty slag and to interfere in other ways with the smooth running of the blast furnace. ... from the presence of pyrite and copper pyrites. Garnet, epidote, pyroxene, and apatite are found in the wall rock as well as in the ore. The magnetite deposits ...

Nov 23, 2011· NEW POINTS MADE FROM IRON ORE SLAG ... .If you look at eared Dlton you will see a very small ball bearing like ball in the right side,that is from the iron ball is no bigger than .015 ...

Blast furnace slag is recovered by melting separation from blast furnaces that produce molten pig iron. It consists of nonferrous components contained in the iron ore together with limestone as an auxiliary materials and ash from coke. Approximately 290 kg of slag is generated for each ton of pig iron.

99% of all meteorites are attracted to a strong magnet. (As are metal artifacts, slag and iron ore) Or if the object is small, hang it or the magnet from a string. This is used as a preliminary test and is recommended to new collectors. If your specimen does not pass this test it is probably NOT a meteorite!

Other historic remnants include the blue hematite rocks you''ll find along the pathways and trails surrounding these iron furnaces. These rocks were formed as a byproduct of the iron ore smelting process that took place on these lands. They are considered an historic artifact, much of them now at least 150 years old, and they are not to be removed.

which produce the types of iron slag most likely to be found on archaeological sites in both rural and urban areas. Smelting is the production of iron from ore and fuel in a smelting furnace. The products are spongy mass called an unconsolidated bloom ‐ raw iron with

May 20, 2017· The raw source of iron is iron ore. Iron ore comes in the form of rocks or other sediments. These are composed of iron oxides, which we try to reduce, and the unwanted ''gangue materials'' which take the form of silicates and alumina, in other words the ''rock'' part of the ore. ... Separation of Iron Slag – Above 1100°C ...

I use the term here to also include any manmade, rocklike byproduct of heating things to high temperature. Thus, clinkers are a form of slag. Slags catch people attention because of their morphology. Many slags contain metal from inefficient separation of metal from the ore and, thus, will attract a magnet.

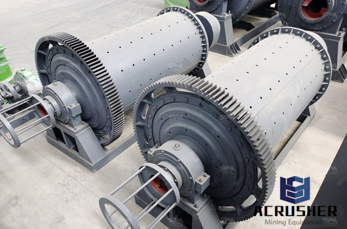

Slag crushing equipment in Europe,slag crusher plant for sale,supplier. Our slag crushing equipment is intended to generate the highest high quality end products in processing slag, tough and soft rock, sand and gravel, ore and . »More detailed

Oct 01, 2019· Nonferrous smelting, used to refine copper, lead, and similar metals, produces highly ferrous slag, as iron is an undesired element. Ferrous smelting, such as that used to produce steel, creates non ferrous slag, as all the iron is used in the smelting process. After slag is allowed to age, it can be sold for use in other industrial processes.

basalt or diabase. Slag wool is made primarily from iron ore blast Furnace slag. As . with any product capable of producing airborne dust, con cerns regarding the health and safety effects of rock and slag wool are understandable. How ever. few materials have been studied as extensively as min eral wool and still found to . be safe

Iron Blast Furnace Slag (BFS) This is the coproduct from the reduction of iron ores to produce molten iron and molten slag. 1. When allowed to cool slowly to a crystalline rod< form It becomes a light gray vesicular rock known as AirCooled Blast Furnace Slag. Principle uses include:

Mineral Rocks Ore Crushing Machines. Stedman impact crushers, mills, and grinders are used in nearly every mineral and mining industry. Whether you are processing iron ore, coal, rock, salt, wood chips, or clay – to name a few – we have your solution to size reduction.

Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore. These ingredients, when heated at high temperatures form a rocklike substance that is ground into the .

The smoke and din of a busy iron town are gone now. All that remain are piles of rock rubble, a few flakes of slag, and memories of a distant enterprise. Hot air Slag impurities Molten iron Charcoal Iron Ore Limestone Basic Blast Furnace Operation Casting room Recipe for Pig Iron Pour 900 pounds iron ore 30 bushels of charcoal 155 pounds of ...

Surestrike impact breakers are have been successfully used to break the hardest rock such as granite, iron ore, basalt and field stone for over two decades. Softer rock such as gypsum and limestone are easily broken without tools becoming stuck. The Surestrike impact hammers have the power to effectively break slag and steel.

WhatsApp)

WhatsApp)