The Nile Co., Ltd.

Ball Mill . Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill .

WhatsApp)

WhatsApp)

Ball Mill . Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill .

With more than 100 years of experience in ball mill technology, ''s ball mills are designed for long life and minimum maintenance. They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits.

Ball Mill Jars from Hunan Togoal Instrument Equipment Co., Ltd.. Search High Quality Ball Mill Jars Manufacturing and Exporting supplier on

Boliden Allis () 24''x9'' 3,000 HP SAG Mill Available Aug 26; King Sells HP800 Cone Crusher for Project in Canada Aug 26; King Sells Mobile Skidded 4x5 Ball Mill Jul 21; King King Sells Ships Flotation Cells, Drum Filter, Thickener Pumps For Project In Mexico Jul 21; King Sells Ships Unused Feeco 250kW Agglomerator Jul 21

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size.

6451 TransCanada Hwy Savona, BC V0K 2J0

Gold Mining Equipment List. Making a complete list of gold mining equipment starts with defining the type of gold mining you are doing and the budget you have at your disposal. The type of mining relates to hard rock, eluvial, or placer; alluvial capital budget you have to invest in buying your equipment with dictate the scale at which you want to mine and influence the longterm ...

BRAND NEW HARD ROCK MINING equipment available for immediate sale, from Mt. Baker Mining and Metals. We are a USA manufacturer located in Bellingham, WA. Call us today at (360) for more information. 3''x6'' Ball Mill (1TPH), complete with drive, 20hp motor, balls, frame 31,100

RETSCH is active in the fields of homogenizing laboratory samples for analysis as well as particle size analysis of solid substances.

A devise that breaks solid materials into smaller pieces by grinding, crushing or cutting. Milling covers a wide variety of difference operations and machines.

Ball Mills | Extruders | Mixers Pug Mills | Scales | Sink Traps Slab Rollers | Spraybooths | Ware Carts Wedging Tables | Wheels. At The Ceramic Shop, we provide the best in quality equipment for artists, schools, studios and potters working in the ceramic industry. If you are looking for ball mills, pug mills, extruders, mixers, slab rollers, sink traps, and more, we have it all here in our ...

Lab Jar Mill. Lab Roll Ball Mill. Dual Planetary Ball Mill. Cryogenic Planetary Ball Mill. Vertical Planetary Ball Mill for Glove Box Use. Heavyduty Fulldirectional Planetary Ball Mill. Laboratory FullDirectional Planetary Ball Mill. Laboratory Horizontal Planetary Ball Mill. Mini Vertical Planetary Ball Mill

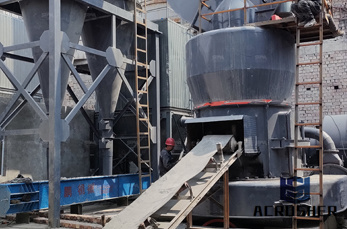

roller mill(HCH): It can produce ultrafine powder, low energy consumption low investment cost, large scale ring roller mill has good market prospect. Disadvantage: low output. mill +classifying: High energy consumption, it is almost obsolete in nonmetallic mineral industry.

Rotor Mills ZM 200, TWISTER, SR 300, SK 300. Cutting Mills SM 100, SM 200, SM 300, SM 400. Knife Mills GM 200, GM 300. Mortar Grinders RM 200. Disc Mills RS 200, RS 300, DM 200, DM 400. Ball Mills Emax, MM 200, MM 400, MM 500 nano, MM 500 cryo, CryoMill, PM 100, PM 100 CM, PM 200, PM 400, PM GrindControl, XRDMill McCrone, TM 300, TM 500 ...

Ball mills for superfine calcium carbonate. Ball mill classifier systems have been improved over time and are now capable of achieving much finer products. In the past, a particle size with a D97 of 10 microns was only possible. Now particle sizes down to a D97 of less than microns can be achieved, with a D50 in the range of microns.

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming ...

DOVE Ball Mills are made of high – grade cast and carbon steel for extra strength, long and troublefree operations. Warranty Program All DOVE equipment carry a 2 years (24 months) standard Manufacturer Warranty, which can be extended to 5 years, in addition to lifetime spare parts supply service.

Vibratory Grinding Mills Size Reduction Equipment Specifically designed for wet grinding, the low amplitude VibroEnergy Grinding Mills range from ft³ ( liters) to 113 ft³ (3,200 liters) of volume. Wet Grinding Mill Models: M185, M18, M38, M45, M60, M70, M80

The ball mill machines mainly include: raw mill, coal ball mill, ore ball mill, small ball mill, wet ball mill, ceramic ball mill, overflow ball mill, as well as vertical ball mill, rod mill and automatic/semiautomatic mill and other industrial milling equipment.

Ball Mills Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800''s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

Cement Plant Equipment. Besides supplying the complete cement plants on turnkey basis, Chanderpur Works also manufacturing cement plant equipment such as cement ball mills, material handling equipment, Classifier and feeders etc. Chanderpur Works Pvt. Ltd. has already supplied these cement plant equipment to some major multinational companies like LOESCHE India, GEBR Pfeiffer, .

It is crucial that the equipment used for milling and grinding can withstand such harsh materials. Our range of milling and grinding technologies have been tried and tested around the globe. Our vertical roller mills, horizontal mills, hydraulic roller presses and stirred mills have for many years offered efficient milling and grinding ...

Wet Grid Ball Mill . Capacity: Feed Size: ≤25 mm. Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc. The size of ore shall not exceed 65mm and the best feed size is under 6mm.

The Mine Mill Equipment Cost Guide covers more than 3,000 items of mobile, portable, and stationary equipment commonly required by mining and milling operations. Select from a full range of sizes and types, with productivity information for many items.

WhatsApp)

WhatsApp)