How to price 50 mt hour cement grinding unit YouTube

Dec 09, 2016· This video is unavailable. Watch Queue Queue. Watch Queue Queue

WhatsApp)

WhatsApp)

Dec 09, 2016· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Unused LOESCHE LM D Vertical Roller Mill. New Surplus LOESCHE Vertical Roller Mill, specifically designed for grinding PETCOKE (could also be used for coal). Capacity will depend on the spec of the petcoke, but will be in the range of 2535 tons per hour. This mill .

Ton Per Hour Cement Vertical Mill. Cement mill with a capacity of 15 tons of hours ball mill 100 ton per hour crusher prices crusher mills 50 60 ton per hour cement millstone crusher and grinding mill0 60 ton per hour cement milltone crusher with production capacity of 500 tons per 2012 grinding ball prices per ton. Chat Online

Pug Mills Federal Equipment Company, the trusted name in used processing equipment provides reliable used industrial and process equipment at competitive prices. To get started, go to the top of any page, click the register button and register as a member of our site.

15 tons per hour of cement Mill. Qeustion: may i know what kind of machine are you interested in? Answer: 15 tons per hour of cement Mill. Location: IRAN. Products: Vertical Roller Mill, MTM Trapezium Grinder, T130X Reinforced Ultrafine Mill, Raymond Mill

Large roadportable plants can crush concrete and asphalt rubble at 600 tons per hour or more. These systems normally consist of a rubble crusher, side discharge conveyor, screening plant, and a return conveyor from the screen to the crusher inlet for reprocessing oversize materials.

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant.

Raymond® Roller Mills Deliver Maximum Productivity Nominal capacities of Raymond® Roller Mill Systems with typical materials Approximate STPH (short tons per hour) Name Manufacturer Rate Cap. lbs/hr Motor HP 3036 Raymond High Side Roller Mill Raymond 30/30 4237 Raymond High Side Roller Mill Raymond 60/40

Alberici served as general contractor for a 7,000tonperday (TPD) expansion of Buzzi Unicem USA''s Festus cement plant. The expansion involved replacement of key portions of Buzzi''s existing 40yearold plant with an innovative preheater pyrotechnology system that allows for more environmentallyfriendly and costeffective cement production.

mini cement 20 ton per day depalenrammersnl. mini cement 20 ton per day 1 ton per hour / 20 ton per day Complete Set Rice Mill, View rice mill 1 ton per hour / 20 ton per day Complete Set Rice Mill,, New, Hubei, China (Mainland), fangfangSource from Ezhou Xingfang Grinding It indies that it''s the top choice model for small and medium rice processing plant in domestic at present based on ...

A cement grinding mill "A" with a capacity of 50 tons per hours utilizes forged steel grinding balls costing P12, 000 per ton, which have a wear rate of 100 grams per ton cement milled. Another cement mill "B" if the same capacity uses high chrome steel grinding bans costing P30, 000 per ton with wear rate of 10 grams per ton cement milled.

Coal Mill Of 825 Ton Per Hour Spring Loaded Roller. ... Coal vertical roller mill great wall corporation coal vertical roller mill can be widely used for cement electric steel 30 use of vertical roller mill production per ton raw material than traditional ball mill.

grinding mill 100 tons hourly – Crusher South Africa. Stone Crusher With Production Capacity Of 500 Tons Per Hour . we need 50 tons per 24 hour and 100 . 150 tons per hour crusher Grinding Mill .

Nov 15, 2015· A cement grinding mill "A" with a capacity of 50 tons per hour utilizes forged steel grinding balls costing P12,000 per ton, which have a wear rate of 100 grams per ton cement milled. Another cement mill "B" of the same capacity uses high chrome steel grinding balls costing P50,000 per ton with a wear rate of 20 grams per ton cement milled.

Flow Rate By Mass Converter / Metric / Tonne Per Hour [t/hour] Online converter page for a specific unit. Here you can make instant conversion from this unit to all other compatible units.

ton per hour cement mill ; Patent EPA1 Grinding aid Google Patents. which is used during the stage of grinding the cement clinker in a grinding mill. 40 minutes in a cement plant, Mill ...: prestige wet grinder price in hyderabad models

30 ton per gold milling – Double Equipment Mining. equipment list for mining 30 ton per hour, rock crushing plant. . cement grinding aid composition; surface ... Request Quotation. This page is provide professional 10 ton per hour coal mill information for you, we have livechat to answer you 10 ton per hour coal mill question here.

10 tonnes per hour and 20 tph ball mill for a small mineral processing plant and milling balls ... ball mill classifier lv technology public company limited. 176, 2003, century cement, india, ball mill, static, coal. . ... 10 ton per hour crusher export ball mill 10 ton per hour cost price stone crusher machine 10 tonne per hour of ball mill ...

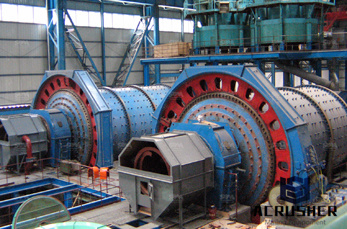

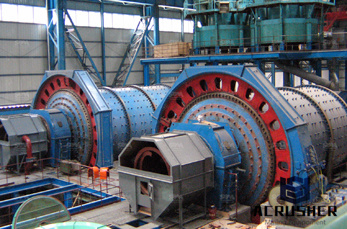

Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc. The applications of ball mills are ubiquitous in mineral

Our powerful pug mill continuous mixing systems offer cost effective mixing for wet or dry materials. The dual shafts in this system operate independently, with a separate motor, v belt, and gear reducer composition for sequential starting.

Estimates of Electricity Requirements for the Recovery of Mineral Commodities, with Examples ... underground cutandfill mining at 1,500 metric tons per day using the carboninpulp leach ... kilowatthour (kWh) per unit basis, primarily the metric ton (ton) or troy ounce. Data contained

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Pub. L. 95–95, title I, §127(b), Aug. 7, 1977, 91 Stat. 741, directed Administrator, within 1 year after Aug. 7, 1977, to report to Congress on consequences of that portion of definition of "major emitting facility" under this subpart which applies to facilities with potential to emit 250 tons per year or more.

Crushers from LT, raw meal silos from FL /KHD Humboldt and vertical roller mills from Loesche, Germany are few among the large list of suppliers. The combined capacity of the four plants is 10 million tonnes per annum. Apart from the four cement plants, the .

WhatsApp)

WhatsApp)